BFF awards GEA a contract to build new food-grade (precision) fermentation upscaling line

New pilot capacity strengthens Dutch infrastructure for scale-up and validation of New Food technologies.

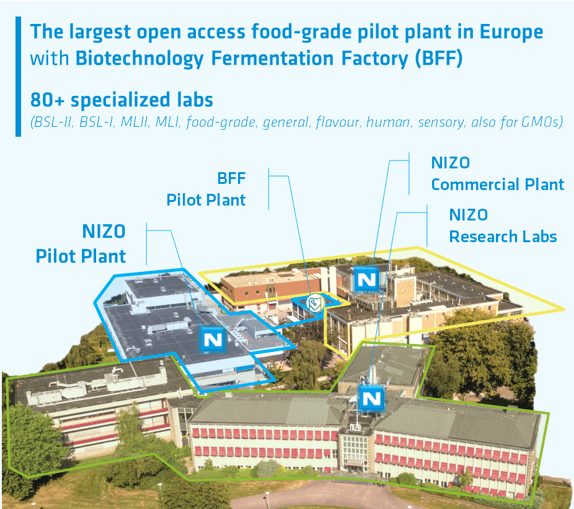

Biotechnology Fermentation Factory (BFF) has awarded GEA the contract to supply, install and commission a new food-grade (precision)fermentation upscaling line at its facility on the NIZO Food Innovation Campus in Ede. The line — featuring 1,000-liter and 10,000-liter fermenters with integrated upstream and primary recovery steps — is a key element in expanding the Netherlands’ mid-scale fermentation infrastructure and strengthening Europe’s capacity to bring biotechnology-enabled food innovations to market.

The new installation forms part of BFF’s open-access scale-up environment, designed to help companies validate fermentation processes under realistic, food-grade conditions and generate decision-grade datasets to support investors, regulatory and commercial decision-making. The facility will operate alongside BFF’s existing 10–30 liter pre-pilot systems and its 800 liter and 4,000 liter biomass-fermentation lines. Following primary recovery, pilot material can be transferred directly into the existing DSP pilot plant at NIZO, enabling end-to-end validation workflows within the same campus.

Closing a critical gap in the European scale-up landscape

Many precision- and biomass-fermentation projects stall between laboratory proof-of-concept and the first commercial investment decision. By providing shared access to food-grade pilot capacity, BFF supports innovators in overcoming this “missing middle”, reducing risk and accelerating movement from TRL 4–7. BFF’s open-access model serves both food and ingredient biotech companies and technology providers developing new tools for fermentation performance, such as sensing, process-control and metabolic-monitoring solutions. Validating these technologies in real, food-grade environments is essential for adoption by industry.

Our aim is straightforward: to give the industry dependable, open-access capacity to validate fermentation processes under food-grade, scalable conditions. With GEA supplying this new precision-fermentation line, companies will gain the technical reliability and speed they need to move confidently from lab development toward industrial readiness.

Marcel Oogink, Managing Director, Biotechnology Fermentation Factory

Food-grade pilot capacity is a critical link many innovators have been missing. By delivering BFF’s new line, we help teams validate their processes faster and more reliably — and we strengthen GEA’s role where biotechnology meets scalable manufacturing. This pilot environment enables application-ready material and decision-grade datasets that support the transition toward commercial production.

Frederieke Reiners, Vice President New Food, GEA

Financing and strategic context

The expansion of BFF’s pilot capability is supported by the Dutch National Growth Fund program Cellulaire Agricultuur Nederland (CAN), with regional co-funding from Oost NL and in-kind contributions from NIZO. Together, these investments strengthen the Dutch position as a leading hub for fermentation-based food innovation and enable companies to advance more quickly toward market entry.

About BFF

Biotechnology Fermentation Factory (BFF) is an open-access fermentation scale-up facility on the NIZO Food Innovation Campus in Ede (NL), helping companies bridge the gap between lab development and industrial readiness. Supported by the Dutch National Growth Fund (CAN), BFF serves food- and ingredient-biotech innovators as well as technology providers developing new tools to improve fermentation performance, offering food-grade validation capacity across multiple scales.

About GEA

GEA is one of the world’s largest suppliers of systems and components to the food, beverage and pharmaceutical industries. The international technology group, founded in 1881, focuses on machinery and plants, as well as advanced process technology, components and comprehensive services. For instance, every second pharma separator for essential healthcare products such as vaccines or novel biopharmaceuticals is produced by GEA. In food, every fourth package of pasta or every third chicken nugget are processed with GEA technology.

With more than 18,000 employees, the group generated revenues of about EUR 5.5 billion in more than 150 countries in the 2024 fiscal year. GEA plants, processes, components and services enhance the efficiency and sustainability of customers’ production. They contribute significantly to the reduction of CO2 emissions, plastic usage and food waste. In doing so, GEA makes a key contribution toward a sustainable future, in line with the company’s purpose: ”Engineering for a better world.”